The hygienic production, storage and delivery of pharmaceuticals, cosmetics and foodstuffs place high demands on the cleanability of production areas as well as storage and transport containers. Complex plants with CIP cleaning systems are required to ensure not only product safety and environmental protection, but also compliance with the strict GMP guidelines for quality-assured production.

The efficient design of systems consumes enormous resources and is based on the valuable experience of engineers. Optimally positioning static and dynamic cleaning nozzles is a major challenge. As a result, cleaning systems are reconfigured several times with the help of complex analog tests, but often end up being oversized to be on the safe side.

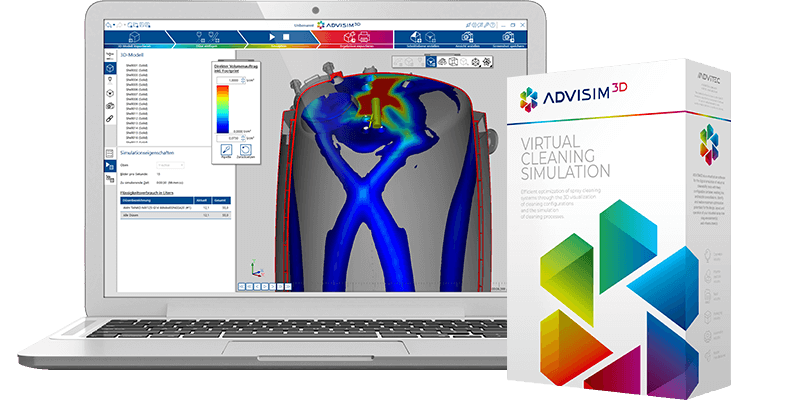

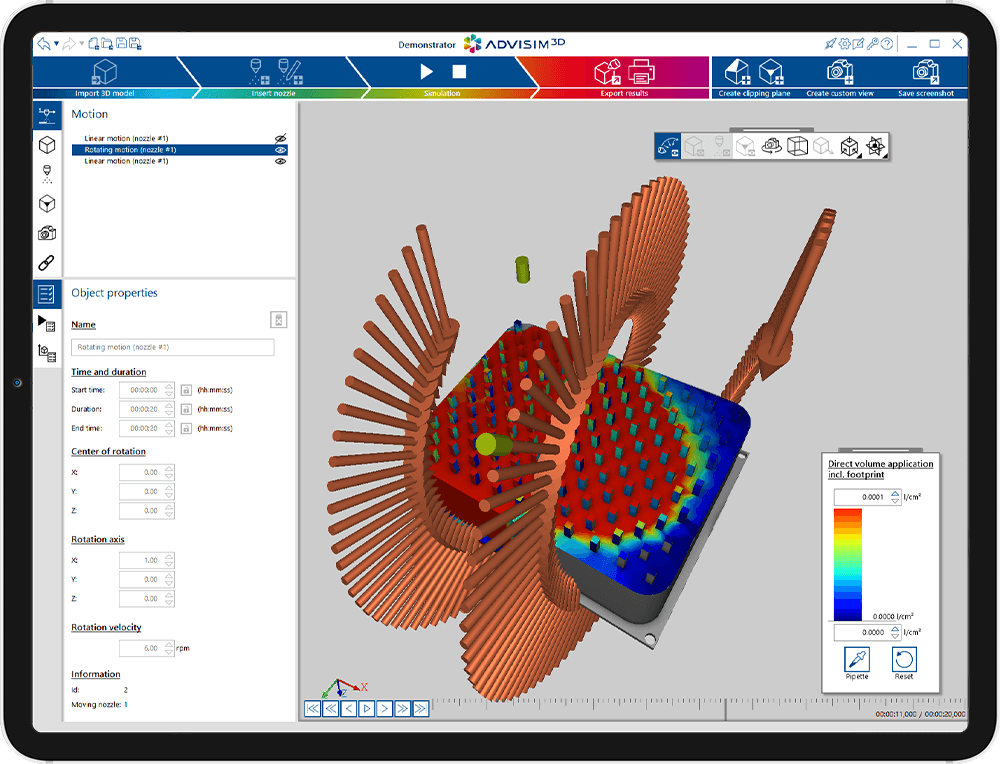

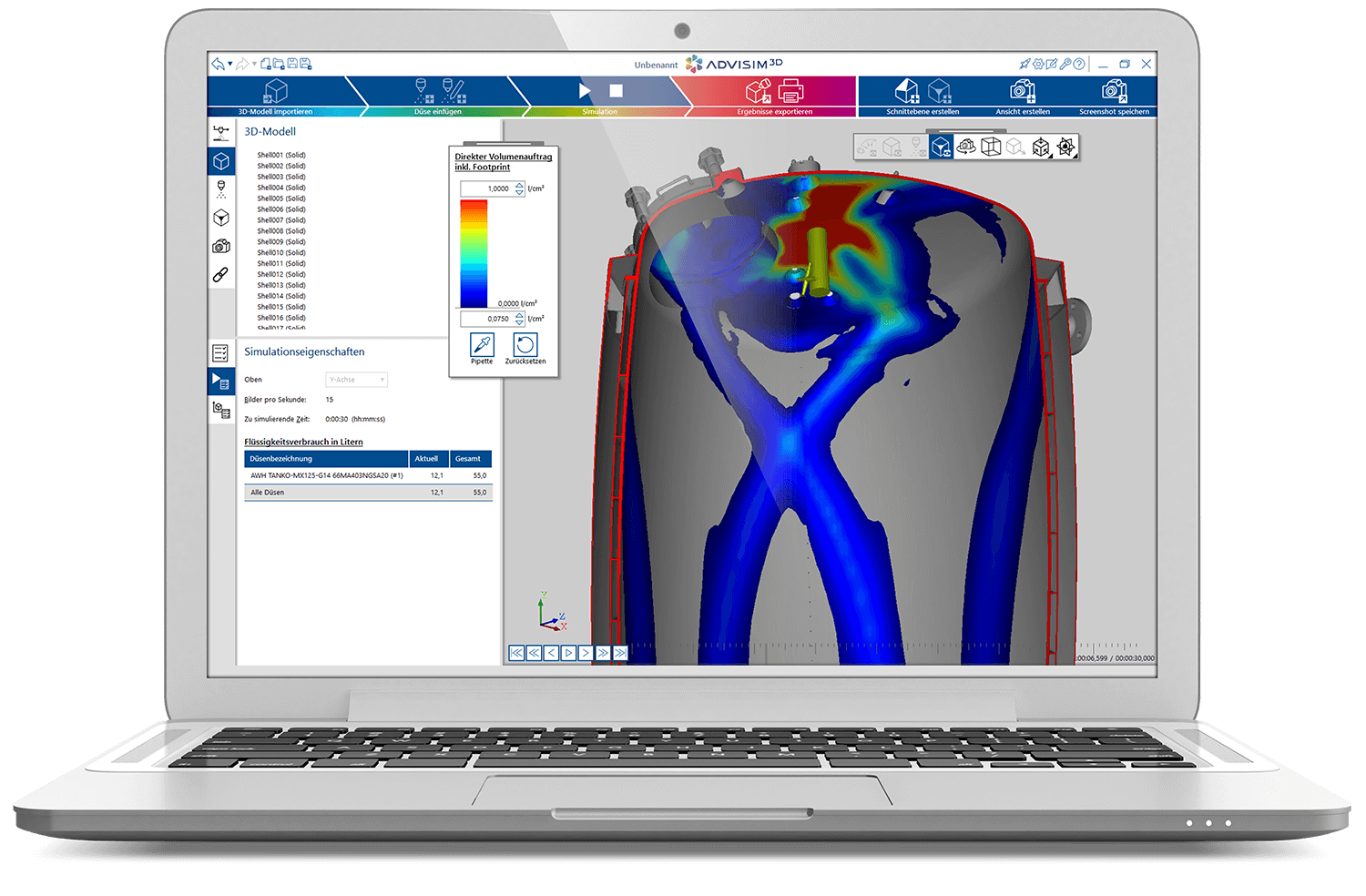

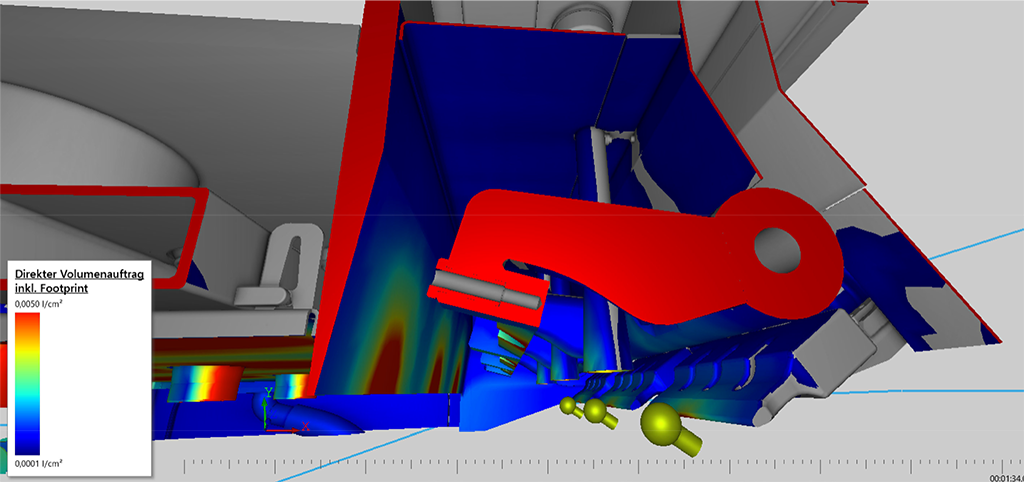

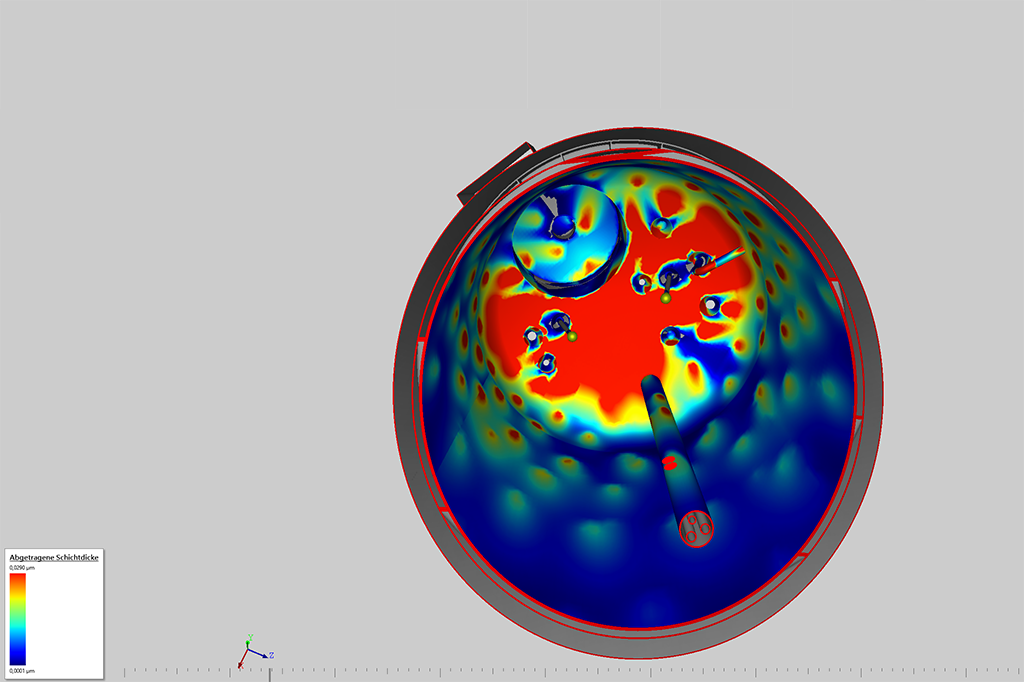

ADVISIM3D reliably simulates industrial spray cleaning processes. It identifies and realizes optimization potentials for GMP-compliant design, layout and operation of professional cleaning environments. With ADVISIM3D, users can make valid statements about spray shadows, volume flow distribution and cleaning effect in order to produce and store safely and hygienically.

Requirement

The hygienic production, storage and delivery of pharmaceuticals, cosmetics and foodstuffs place high demands on the cleanability of production areas as well as storage and transport containers. Complex plants with CIP cleaning systems are required to ensure not only product safety and environmental protection, but also compliance with the strict GMP guidelines for quality-assured production.

Problem

The efficient design of systems is very resource-intensive and is based on the valuable experience of engineers. In particular, the optimal positioning of static and dynamic cleaning nozzles is a major challenge. As a result, cleaning systems are repeatedly reconfigured with complex analog tests and often end up being oversized for safety reasons.

Solution

ADVISIM3D reliably simulates industrial spray cleaning processes. It identifies and realizes optimization potentials for GMP-compliant design, layout and operation of professional cleaning environments. With ADVISIM3D, users can make valid statements about spray shadows, volume flow distribution and cleaning effect in order to produce and store safely and hygienically.

Your digital assistant

In the hands of an innovative engineer, ADVISIM3D unfolds its full potential in the design and optimization of industrial spray cleaning systems. In combination with human expert knowledge about the nature of contaminants, the mode of action of cleaning media and the sensible selection and positioning of nozzles, the virtualization solution supports valid statements about the expected cleaning effect in real operation.

Cleaning scenarios

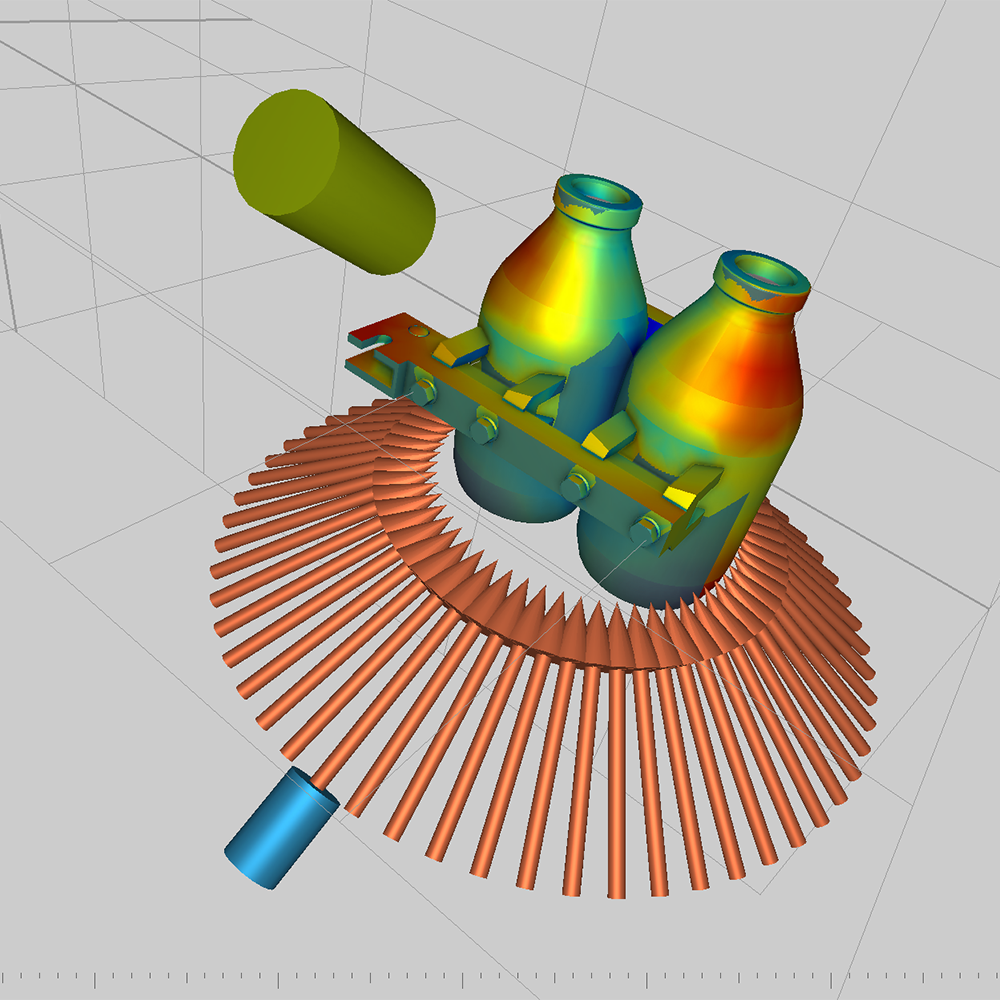

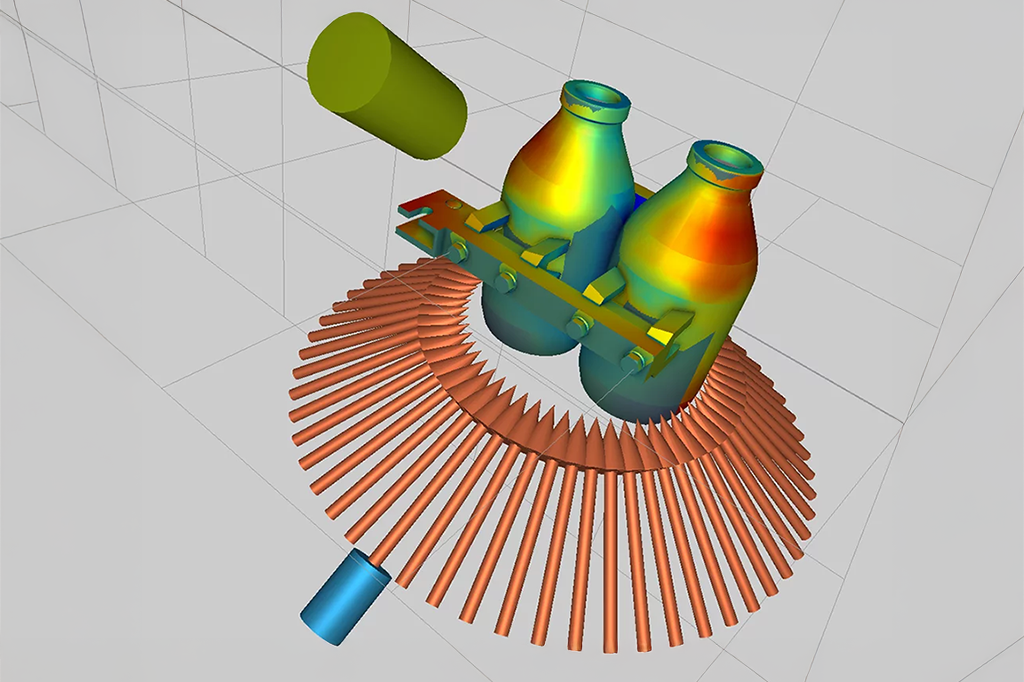

ADVISIM3D is suitable for the virtual simulation of almost all nozzle- and liquid-based cleaning scenarios: from containers, fruit, vegetables and bottles to industrial parts cleaning in baskets and washing lines. It enables the testing of static, dynamic and rotating nozzles in industry-specific environments from the pharmaceutical and chemical industries to the food and packaging industries.

![ADVISIM3D Reinigungsszenarien Bauteilereinigung [Translate to English:] Unterschiedliche Reinigungsszenarios wie Innenreinigung von Tanks, Flaschen- oder Getränkekästenreinigung in Waschstraßen, Teilereinigung in Körben etc.](/fileadmin/advisim3d.de/Bilder/nutzen_branche_einsatz_04.jpg)

Cleaning scenarios

ADVISIM3D is a virtualization solution for the realistic simulation of complex spray cleaning systems.

It is suitable for the design and optimization of a wide variety of cleaning scenarios, such as the interior cleaning of containers, fruit, vegetables, bottles, or beverage crates, as well as industrial component cleaning in baskets or washing lines.

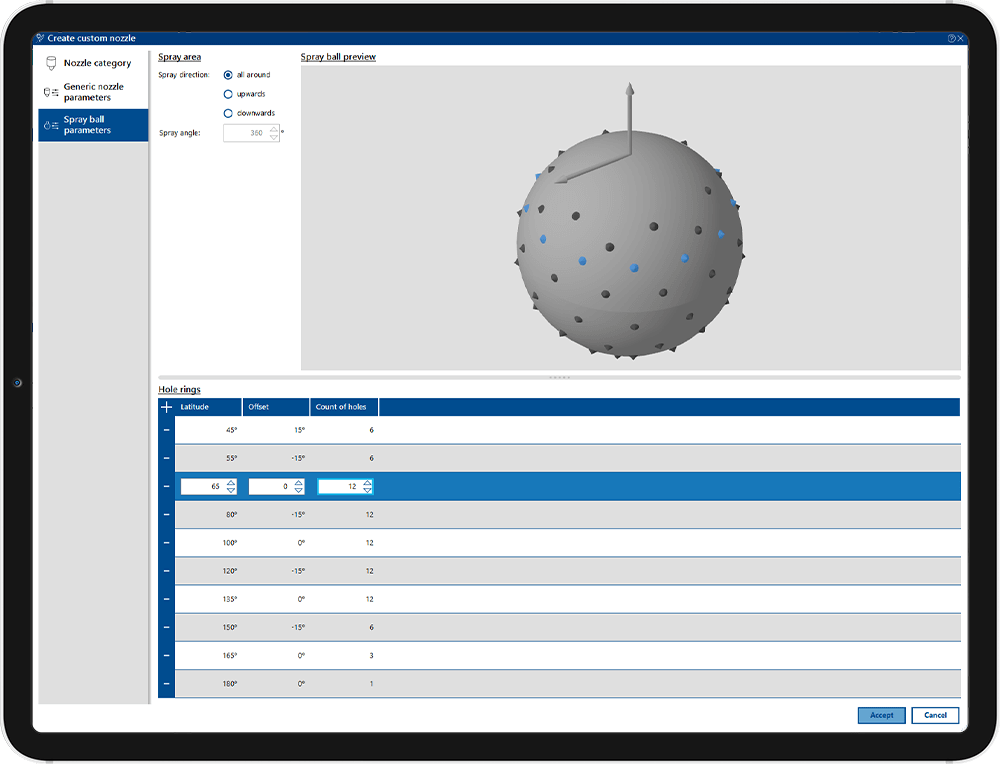

Whether static, dynamic, or rotating, nozzles should provide the fluid with the right volume, the required pressure, and at the right angle to the desired point – ADVISIM3D is your digital assistant for the virtual simulation of almost all nozzle and fluid-based cleaning constellations.

Your Benefits

Environment

- Save cleaning fluid, water and wastewater

- Thanks to the virtual variant comparison less effort for assembly, removal of assembly marks, and model contamination

- Prevention of incorrect dimensioning thanks to optimal system design and resource-efficient layout

- Virtual troubleshooting outside the production environment saves setup time and waste

Highlights

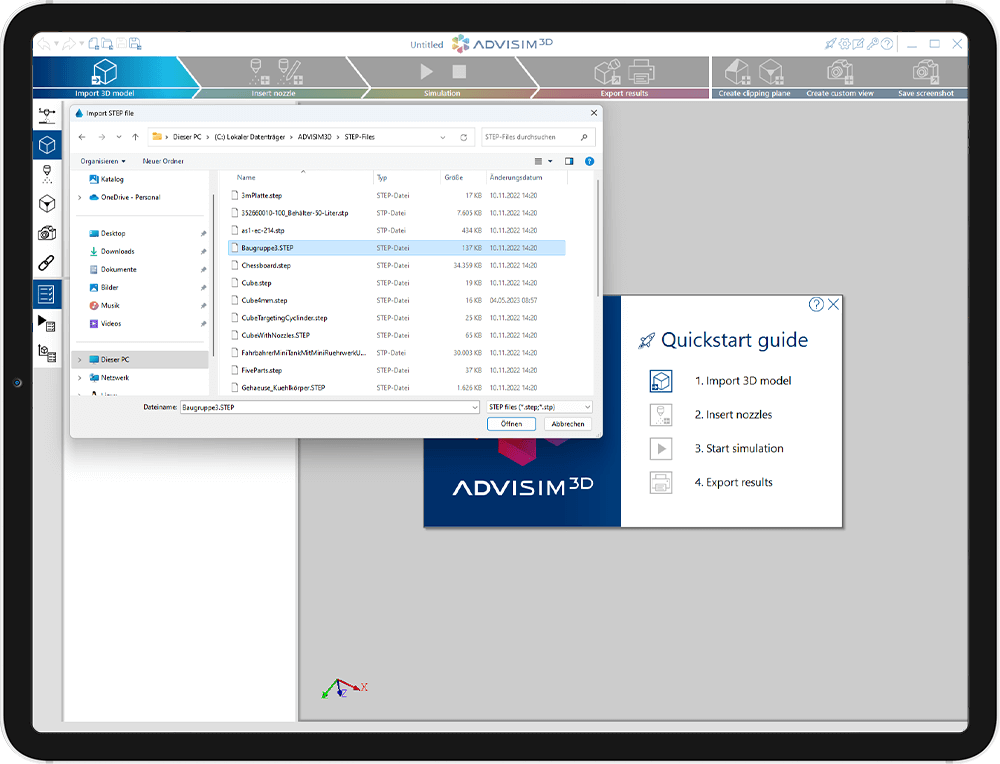

- NEW: Customization of spray balls or designing new ones

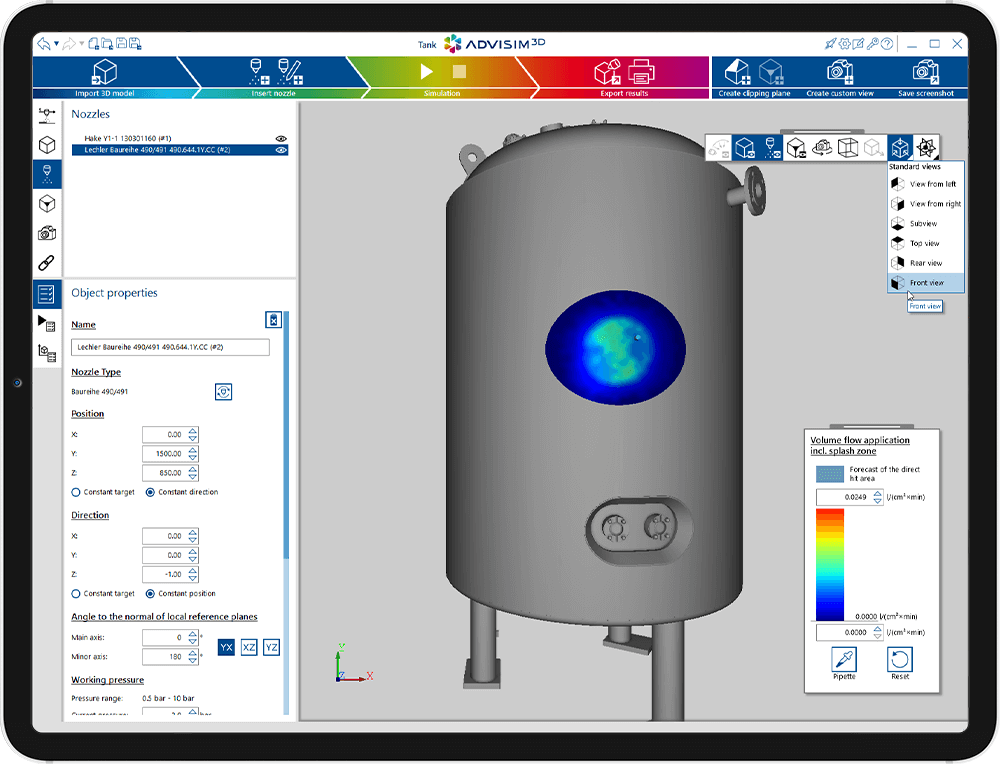

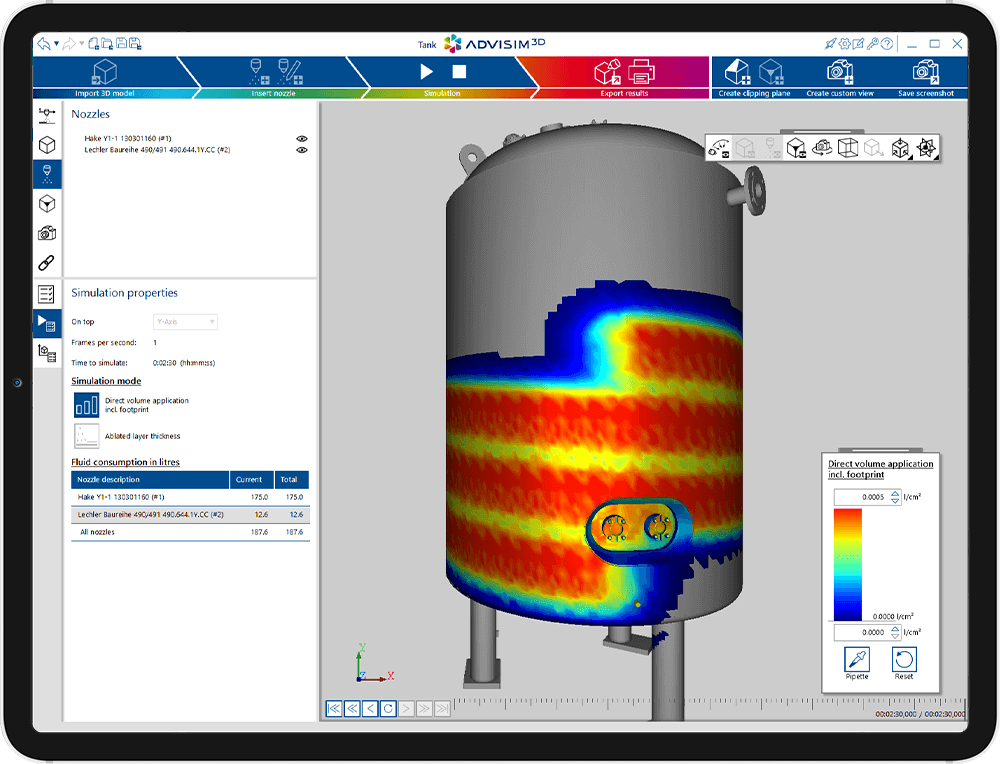

- Instant display of spray shadows with nozzle placement

- Import of complex CAD models in STEP format

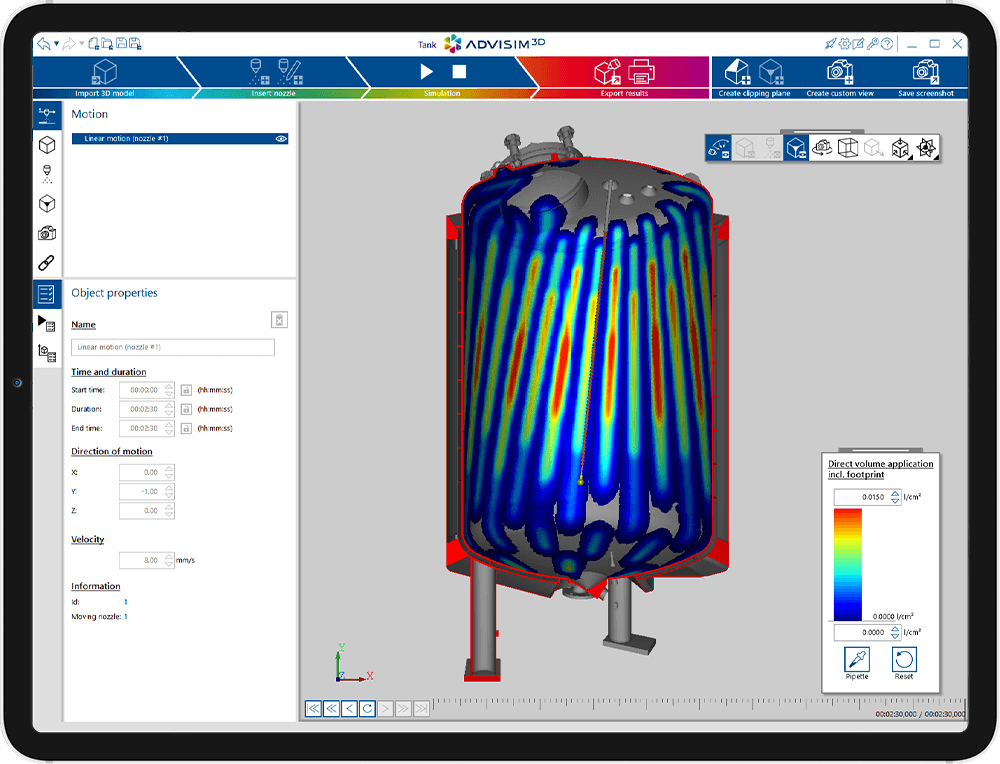

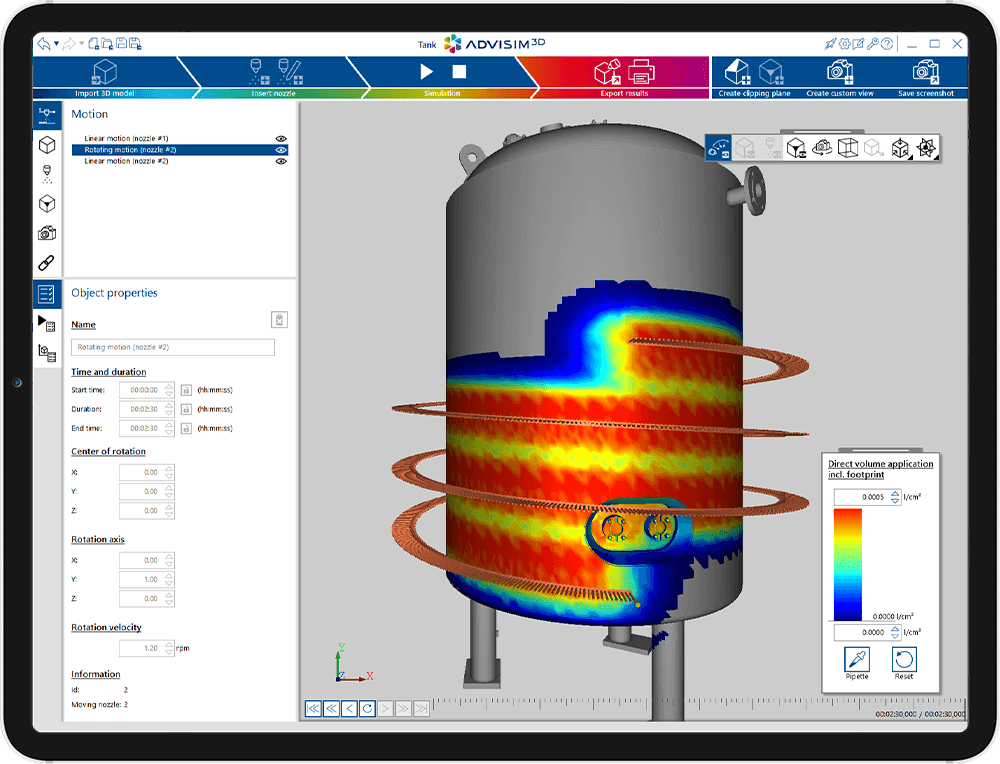

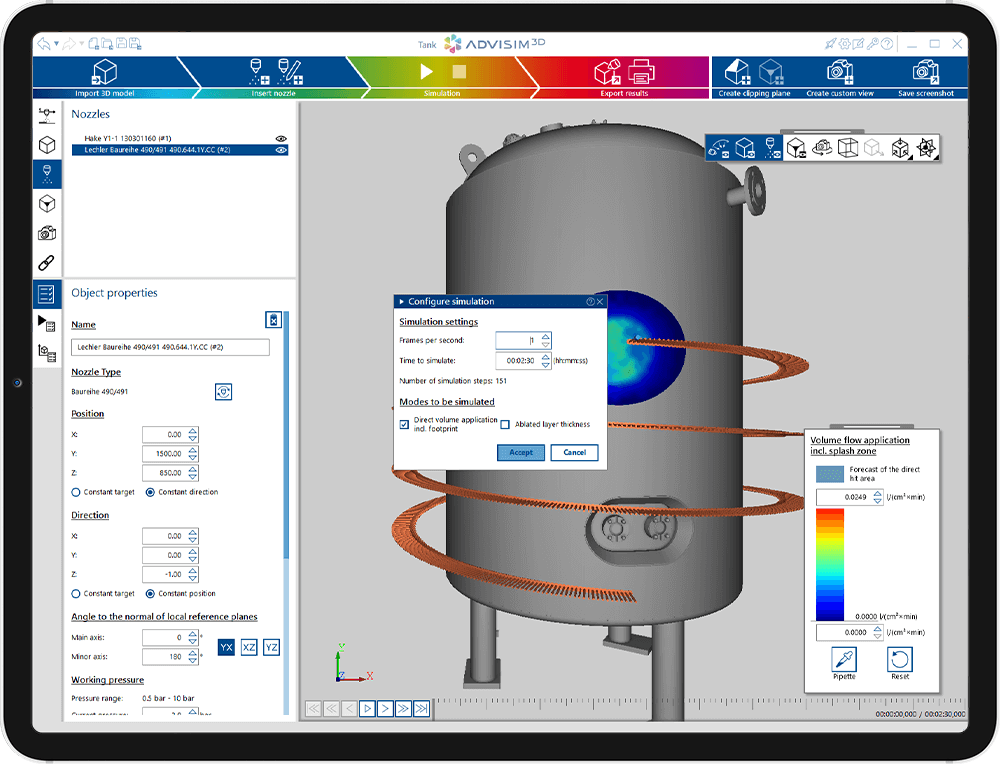

- Simulation of linear and rotating nozzle motions with user-defined time and velocity

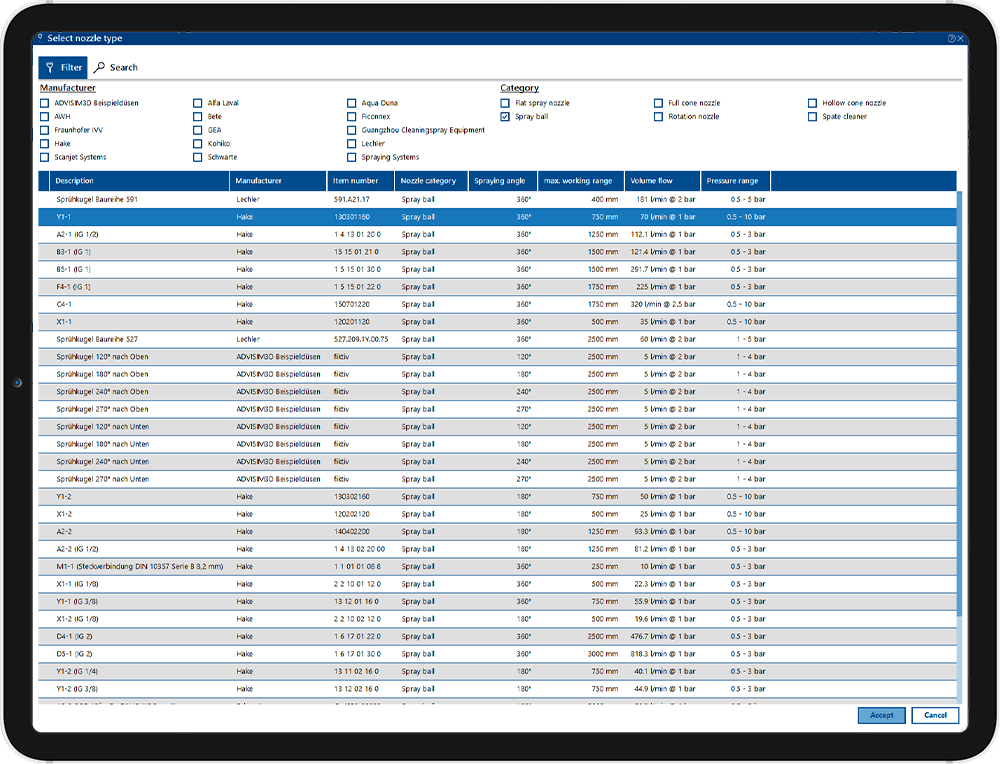

- Large catalog of scientifically measured nozzles from numerous manufacturers

- Precise simulation of the volume flow distribution over time for meaningful proof of cleanability

- Estimation of the cleaning efficiency of a model contamination under the ideal conditions of a scientific laboratory test

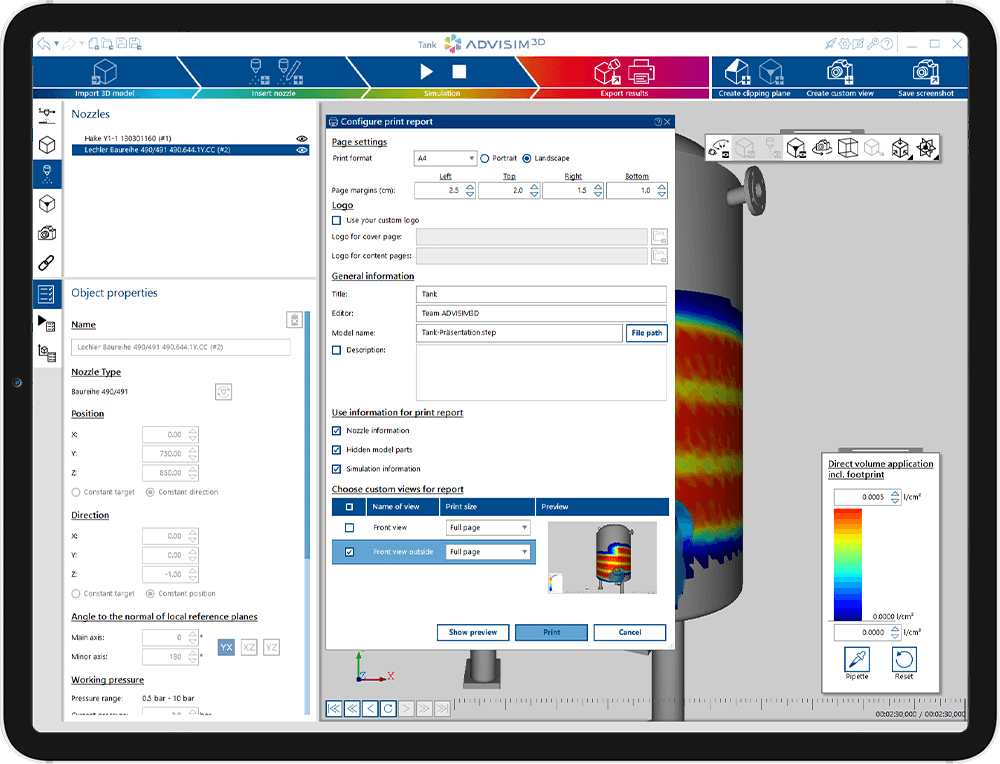

- Simulation results as color visualization and in report form

- Export of the optimal nozzle/cleaning configuration in STEP format for further processing in the CAD program

Do you have any questions? We at ADVITEC will be happy to help you.

Tel +49 351 652622

Who ist behind ADVISIM3D?

ADVISIM3D is a brand product of ADVITEC Informatik GmbH, which has specialized in consulting and managing complex IT projects and software development for around 30 years.

The application is based on the SIMKOR research project for the development of software for virtual cleanability testing and simulation of complex spray cleaning systems. It was funded by the Federal Ministry of Education and Research and successfully implemented over a period of 4 years as a cooperation project with the partners Fraunhofer Institute for Process Engineering and Packaging (IVV) Dresden, Innovations- und Simulationsdienst Festenberg (ISF) and the consortium leader ADVITEC Informatik GmbH.

Company

ADVISIM3D is a product and brand of ADVITEC Informatik GmbH, a company that has been managing and consulting complex IT projects for about 30 years.

The software application is based on the SIMKOR research project designed to develop software for performing virtual cleanability tests and simulating complex spray cleaning systems. It was funded by the German Federal Ministry of Education and Research and successfully realized as a cooperative project with the partners Fraunhofer Institute for Process Engineering and Packaging (IVV) Dresden, the Innovation and Simulation Service Festenberg (ISF) and the consortium leader ADVITEC Informatik GmbH.

There is magic...

in every beginning, this is also true for technical innovations like ADVISIM3D. On the other hand, a convincing, reliable software tool is pretty much the opposite of magic, namely the result of a long, intensive, and iterative development process. ADVISIM3D would also be the first software to be launched on the market and not need to be explained and improved in order to be more oriented to users’ needs.

ADVITEC therefore provides intensive support in the common interest of manufacturers and users and assists with a hotline for inquiries. Our aspiration: The initial magic will gradually be transformed into the industry standard software for virtual cleaning simulation, which has what it takes to become an indispensable digital engineering assistant.

With a support request you agree that you give your consent for the collection and storage of your entered data and IP address for the purpose of contacting you.